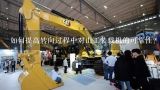

如何提高斗工装载机的安全性?

Answer:

1. Regular Maintenance and Inspection:

- Regularly inspect and maintain all moving parts, electrical connections, and hydraulic lines.

- Conduct pre-trip inspections before each operation to identify and address any potential issues.

- Keep the machine clean and free of debris.

2. Personal Protective Equipment (PPE):

- Ensure that all personnel wear appropriate PPE, such as eye protection, hearing protection, and a hard hat.

- Train workers on proper use and maintenance of PPE.

3. Safe Operation Practices:

- Follow all manufacturer's instructions and safety guidelines.

- Operate the machine at designated speeds and loads.

- Use proper lifting techniques and avoid reaching into the operating area.

4. Emergency Preparedness:

- Develop and implement an emergency response plan that covers various scenarios, including spills, leaks, and machine failures.

- Train personnel on emergency procedures.

5. Training and Education:

- Provide comprehensive training to all operators and users on the safe operation and maintenance of the machine.

- Emphasize the importance of following safety protocols and reporting any unsafe conditions.

6. Compliance with Regulations:

- Ensure that the machine is compliant with all applicable safety regulations and standards.

- Obtain any necessary certifications or approvals.

7. Continuous Improvement:

- Regularly review and update safety procedures and practices.

- Identify and implement opportunities for improvement to enhance safety.

8. Machine Design and Features:

- Consider machine design features that promote safety, such as overload protection, anti-pinch guards, and clear access points.

9. Risk Assessment and Mitigation:

- Identify potential hazards and develop strategies to mitigate them.

- Conduct risk assessments to identify and address potential risks associated with the machine.

10. Consultation with Experts:

- Seek guidance from experienced professionals or safety experts to ensure that safety measures are implemented effectively.